Client

Philip Morris International

Category

CAE Analysis and Calculations, Structural FEM Analysis, Impact Simulation, Crash Test

Tags

Ansys Explicit Dynamics, Consumer Electronics, IQOS

IQOS resistance optimization through advanced simulations.

IQOS drop test - advanced simulation for Philip Morris International

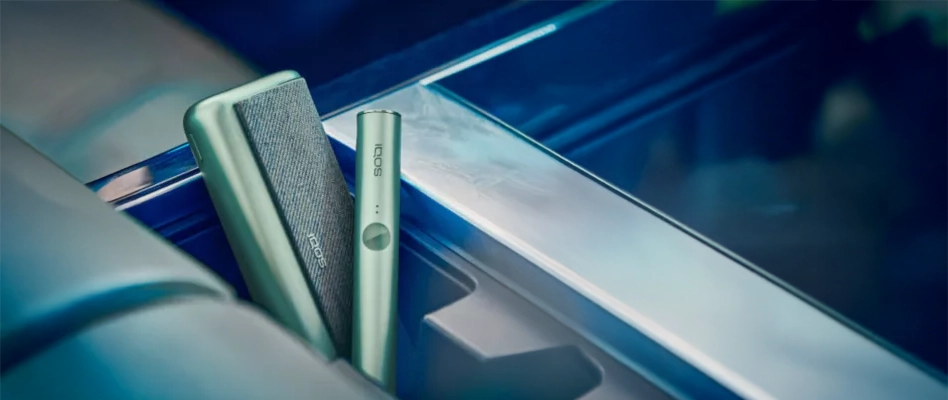

Philip Morris International (PMI), a leader in the transition to a smoke-free future, develops innovative electronic devices such as the IQOS. These products, while compact and high-performance, can be exposed to frequent accidental impacts. Therefore, the main challenge for PMI was to improve the strength of the outer case of the IQOS, specifically to withstand drops without compromising its design or functionality. To address this need, Asotech collaborated closely with PMI, applying virtual engineering and CAE simulation methodologies. The intervention focused on the use of Ansys Explicit Dynamics software, a powerful tool for the analysis of rapid and highly nonlinear impact events. This approach made it possible to predict the behavior of the device in the event of a fall and to identify critical issues early, laying the foundation for a more robust and reliable product.

Increased resistance

of the device

Development time

reduced

Physical prototyping costs

culled

Increased reliability

product

Philip Morris' requirement: increasing the durability of the IQOS Charger

Philip Morris International aimed to ensure high structural strength of the IQOS, particularly against accidental drops from significant heights (such as from a table or pocket). Modern electronic devices, due to their complexity and miniaturization, often have inherent fragilities. The primary objective was to prevent damage to the outer casing, especially at functional openings or foreseeable areas of impact, which could compromise the integrity andreliability of the Philip Morrisproduct . The challenge was to anticipate such issues early in the design phase, avoiding costly iterations of physical prototypes and late modifications.

Modeling IQOS for Virtual Testing.

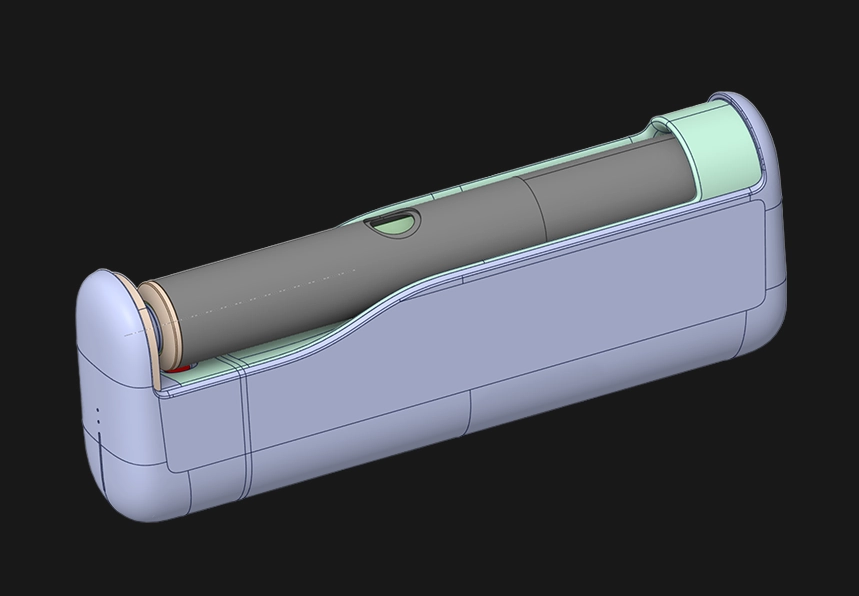

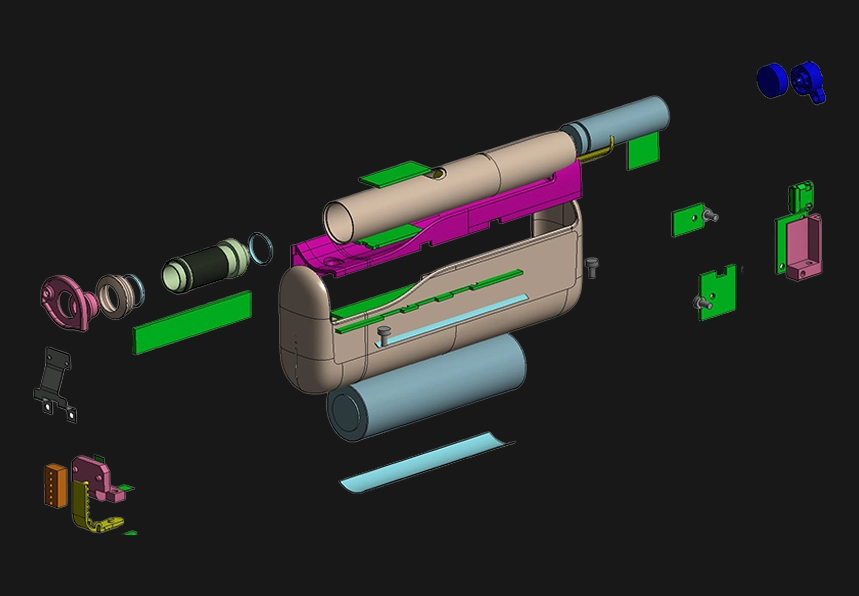

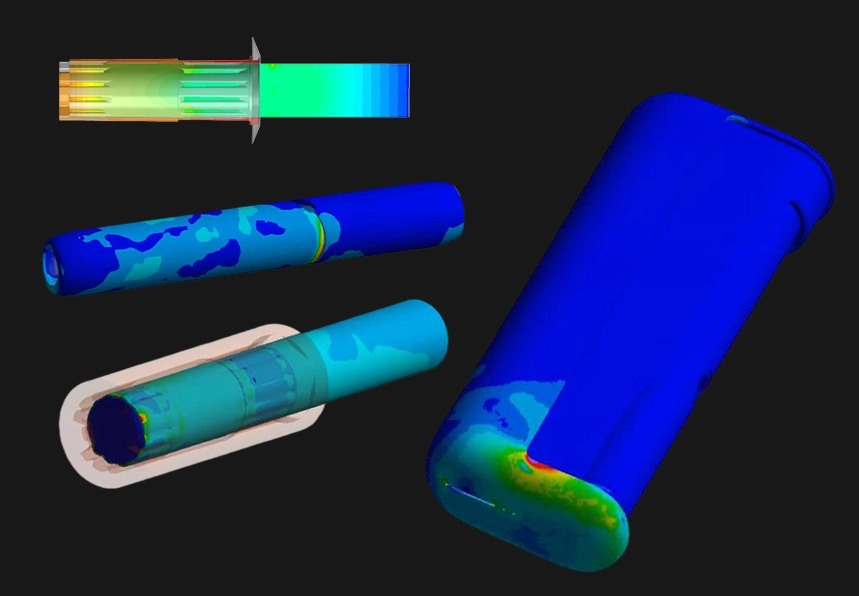

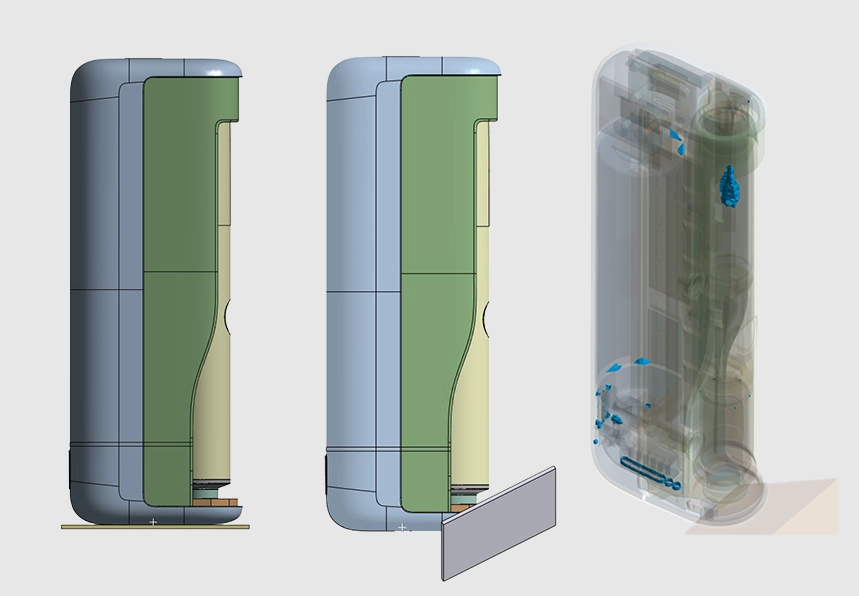

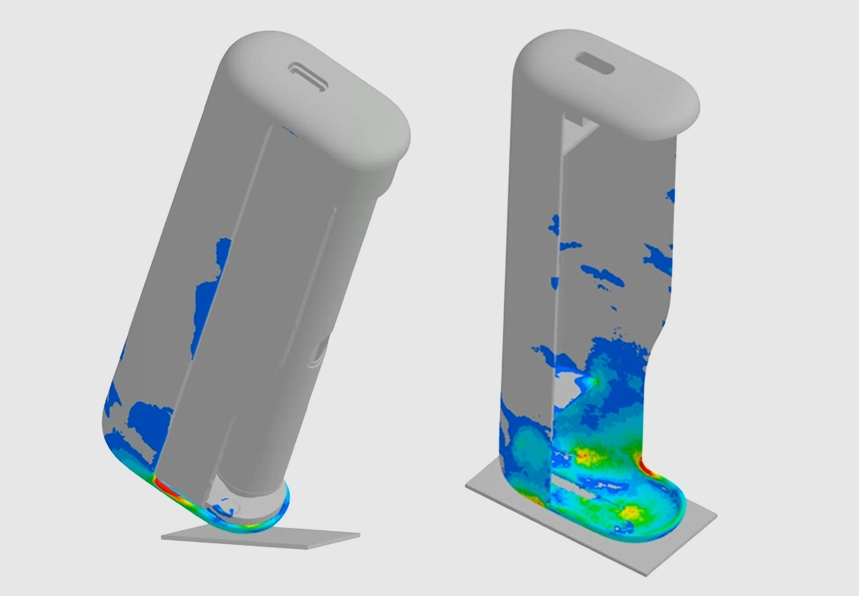

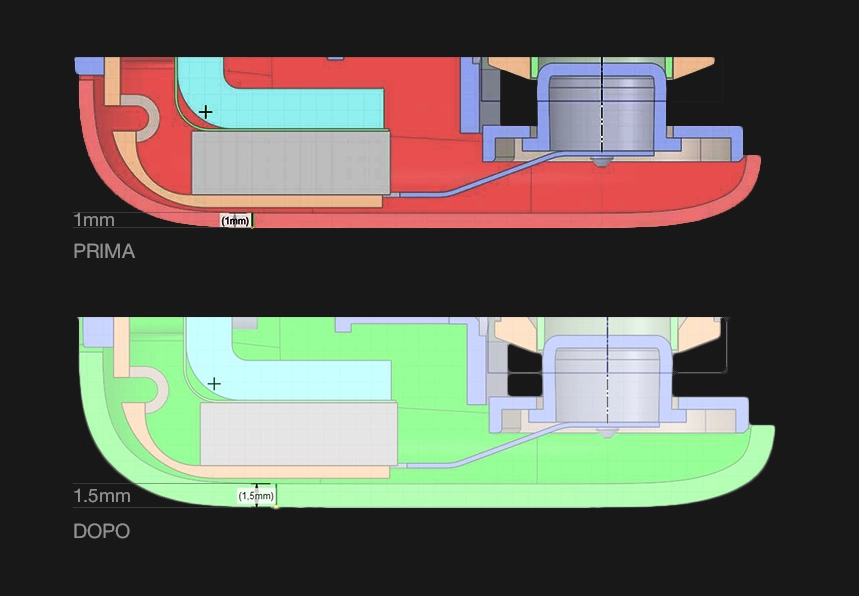

Asotech met the challenge by implementing a virtual engineering process, creating an accurate digital twin for IQOS impact verification. The methodology made use of Ansys Explicit Dynamics, a state-of-the-art software for simulating transient dynamic events such as a fall, characterized by large deformations and nonlinear material behavior in a very short time. The process included detailed 3D modeling, precise definition of material properties (polycarbonate, ABS, aluminum alloys, rubbers), accurate meshing of the FEA model, configuration of interactions and connections between parts, and setting up multiple 1.5-meter IQOS drop test scenarios at different angles. The mass scaling technique was also used, with care taken not to affect the accuracy of the results.

Ansys Simulations and Optimization Design

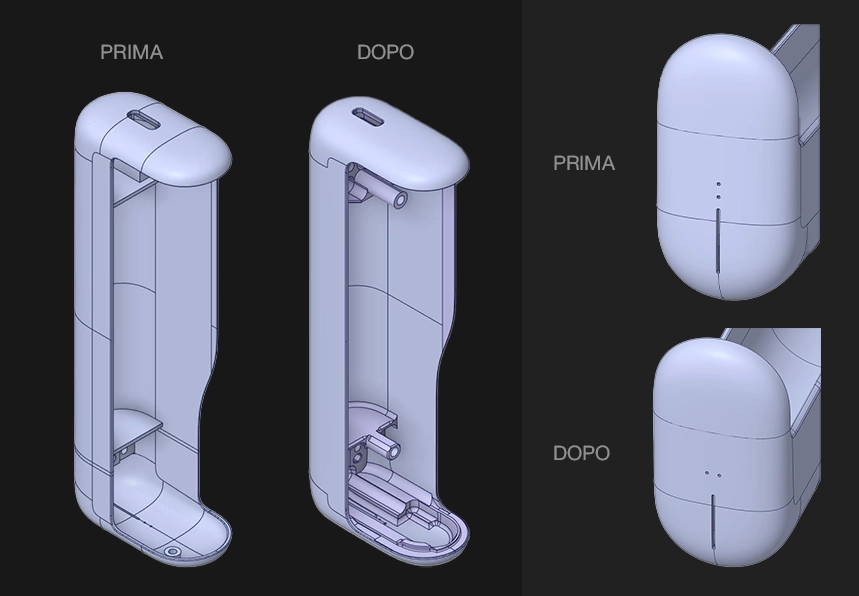

Initial drop test simulations of the IQOS immediately revealed weaknesses in the original design, precisely locating areas at greatest risk of failure, such as air slots and specific frontal impact zones. This in-depth drop analysis allowed them to understand the dynamics of failure. The real added value of Asotech's approach was the ability to quickly and cost-effectively perform dozens of virtual design iterations, testing alternatives such as increasing wall thickness, changing hole placement, introducing reinforcing ribs, and optimizing fillet radii. Physical tests conducted by Philip Morris on prototypes subsequently confirmed the high accuracy of the simulation models, including strain predictions (~2.5 mm), solidifying confidence in the simulation-driven IQOS design optimization process.

Asotech's intervention, through the strategic application ofCAE analysis for Philip Morris and drop test simulations for the IQOS, has generated significant and lasting value for Philip Morris International. The ability to predict and resolve critical structural issues of the IQOS Charger in the virtual phase has not only improved the durability of the IQOS and its overall resilience, but has also enabled a drastic reduction in physical prototypes, resulting in savings in development time and cost. The close collaboration between the team of PMI engineers and Asotech's CAE specialists created a virtuous cycle of design, simulation and validation, leading to the realization of an optimized and more robust final product, ready to face market challenges with greater confidence. Asotech's expertise in advanced simulation proved to be a key factor in the project's success.