'; view

'; view

about

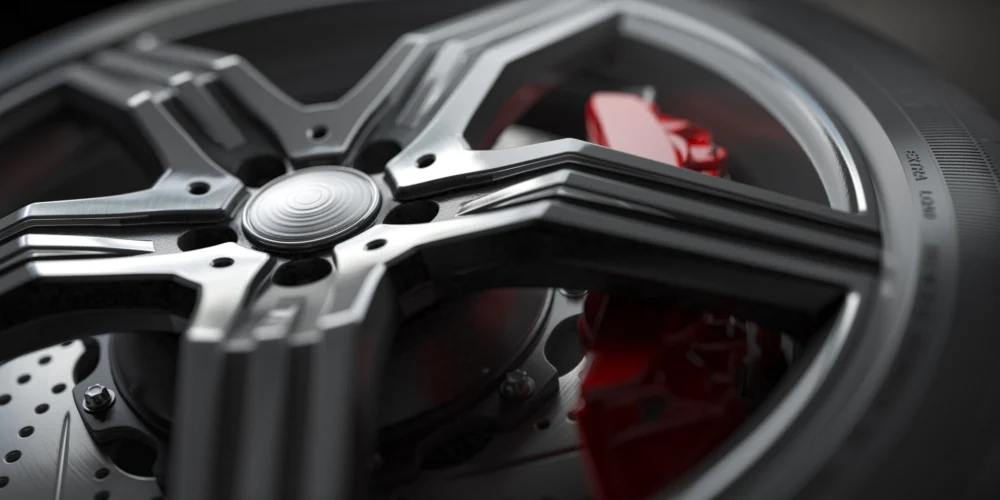

delivering automotive

performance with speed,

accuracy, and control

delivering automotive

performance with speed, accuracy and control

Engineering Consulting for the Automotive Industry

Speed, accuracy, reliability

Automotive is a complex industrial ecosystem that combines design, systems integration, and manufacturability throughout the vehicle supply chain. In this context, every technical choice must balance performance, quality, time, and process constraints.

In the automotive sector, the complexity of systems and time-to-market pressures require rapid and verifiable technical choices, with increasingly early validation. Asotech supports automotive companies in Italy with automotive engineering consulting, combining mechanical design and CAE calculations/simulations to transform complex requirements into robust, consistent solutions ready to advance to industrialization, equipment and processes.

Enhance your automotive projects with reliable and qualified support

Scope of application

Automotive skills applied to other contexts

Racing

Agriculture

The challenges of the automotive industry

The automotive industry is characterized by tight technical constraints, compressed development time, and very high quality and integration requirements. Key challenges include:

1. Weight reduction and performance optimization (without compromise)

Reducing weight means improving efficiency and performance, but it requires a rigorous approach. Rigidity, durability, mounting constraints, and functional requirements must be balanced.

We support technical teams with:

CAD control and assembly consistency

comparative assessments and targeted design choices

structural optimization and technical verification

Special attention to composite/carbon components and finishes

2. Integration between systems and real design constraints.

In the automotive field, each component lives within a complex system: packaging, interfaces, tolerances, and process constraints. We design with a focus on global compatibility, reducing risk and rework.

We intervene on:

- mechanical integration and interference control

packaging and assembly constraints management

consistency between requirements and technical solution

support for architecture choices and functional layout

3. Industrialization and producibility

A "correct" CAD design must also be manufacturable. Tooling, assembly sequences, and layouts affect time, quality, and cost.

We support:

manufacturability (DFM) and technical feasibility

definition of equipment and assembly islands

equipment for carbon-related processes

support for the definition of industrial layout

4. Digital validation: FEM/CFD and thermal for rapid decisions.

When you have to make technical decisions quickly, CAE calculations become a real accelerator. Simulation reduces uncertainties and makes component behavior more predictable.

We perform:

FEM analysis (FEM calculation and simulation)

CFD analysis (fluid dynamic simulations where applicable)

Thermal analysis in support of powertrain and electrification

Find out how we can support you in Automotive

Automotive engineering consulting services

Tailor-made solutions for our customers

We design and develop chassis and shell with attention to robustness, integration, and packaging constraints. We ensure consistency between requirements and solutions, controlling interfaces and mountability. The goal is to reduce iterations and ensure structures ready for validation and advancement.

Interior and exterior finishes car

We support the development of car interiors and exteriors, managing surfaces, aesthetic-functional details and assembly interfaces. By curating compatibility and perceived quality, we make the design more stable in the later stages. When necessary, we align choices with manufacturability and timing requirements.

Carbon and composites

We design components in composite materials and carbon fiber, balancing performance, quality, and integration constraints. We work on geometries, interfaces, and component stability, facilitating an orderly transition to the next steps. The approach is technical, verifiable, and results-oriented.

Mechanical assemblies

We develop vehicle mechanical assemblies with focus on functionality, integration, and compatibility with the overall architecture. We manage constraints, interferences, and assembly consistency to limit rework and design instability. The result is a more controllable system, ready for review and release.

Engine installations

We support the design of motor systems, working on layout, footprint, interfaces and maintainability. We maintain consistency between requirements and solutions, reducing critical integration issues. We support the team in technical choices to accelerate system development and consolidation.

We support electrification projects with a focus on thermal analysis, determinants of performance and reliability. We evaluate operating conditions, integration constraints, and packaging to reduce criticality and rework, providing clear design guidance and technical results to support decisions.

We design mechanical equipment and assembly islands geared toward repeatability, quality, and operational speed. We translate process constraints into consistent technical solutions, reducing errors and set-up times. The goal is to make assembly more stable and controllable.

We perform CAE calculations and simulations to reduce risk and accelerate decisions. On a case-by-case basis, we integrate FEM and CFD analyses, producing concise, traceable reports that support technical reviews, optimization, and automotive project progress, with clear, team-usable outputs.

Industrial layout

We support industrial layout definition by aligning spaces, flows and production constraints with design choices. We intervene to improve consistency between technical office and factory, prevent bottlenecks and make industrialization more linear and controllable.

Leverage our know-how to optimize your automotive projects.

Approach to automotive engineering consulting

How We Work

We Listen to Your Needs

We start with project requirements, constraints and priorities. In this way, we immediately align technical scope, time frame and required outputs.

Technical development and validation

We develop solutions and, when necessary, integrate FEM/CFD calculation activities. As a result, we reduce the risk of rework and make more robust technical choices.

Clear and actionable deliverables

We deliver verifiable results: CAD models, technical documentation, and calculation reports. We also organize the outputs so that the client can use them immediately in decisions, reviews, and project progress.

Our projects for the automotive world

Success stories that demonstrate our expertise.

Do You Have a Project in Mind? Let’s Talk!

We are here to help you transform complexity into reliable solutions, working alongside you in every engineering challenge.