about

engineering precision

into every design.

enginering

precision into

every design.

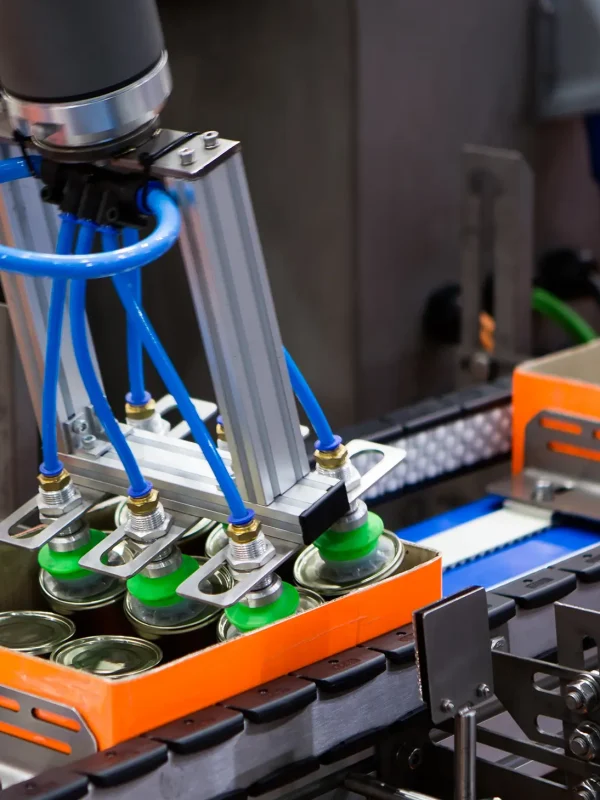

Mechanical Design

Know-how and skills for our clients

We assist our clients and businesses in mechanical design through a shared engineering journey—from the initial concept to industrial development and the final project. We work closely with leading industrial players across various sectors. We enhance their projects with expertise and technical content, improving the performance of existing products or designing new, tailor-made solutions to ensure ease of use for end users.

In this way, we turn entrepreneurial ideas into tangible market successes.

What we do

- Feasibility studies and drafting of technical specifications, Analysis and creation of process flow diagrams

- Project risk analysis using PM methodology (spare parts)

- Competitor technology analysis

- Cost analysis

- Training hours for maintaining technical expertise

- Creation of technical specifications

- Processes Development

- Mechanical design

- Industrialization

- Cost reduction while maintaining product quality

- 3D printing with external services for prototypes or final products

- Construction management (Project management and assistance)

Our technicians skills

- Development of functional mechanical solutions based on client needs and specifications

- Preliminary studies (static and/or dynamic) for overall visualization of geometries and device functionality

- Detailed engineering: 3D modeling and mechanical design, including static, dynamic, animated, and rendered studies, as well as the creation of mechanical components, bill of materials, and assembly drawings (exploded and non-exploded views)

- Structural and performance improvements: kinematic and dynamic calculations, topological modeling, and general optimization of machinery components

Our team

Meet our people:

The project team

Analizziamo, esploriamo, condividiamo per migliorare efficienza ed efficacia di prodotti e processi.

L’obiettivo generale di migliorare la competitività economica che, è parte di ogni progetto, è fronteggiato integrando al contempo la sostenibilità ambientale e sociale per garantire il massimo valore aggiunto.

Analizziamo, esploriamo, condividiamo per migliorare efficienza ed efficacia di prodotti e processi.

L’obiettivo generale di migliorare la competitività economica che, è parte di ogni progetto, è fronteggiato integrando al contempo la sostenibilità ambientale e sociale per garantire il massimo valore aggiunto.

Mechanical Design Industries

- Energy

- Machinery (Filling)

- Machinery (Packaging)

- Systems

- Machines

- Amusement rides

- Equipment

- Automotive & Agriculture

- Components

- Consumer

- Construction & Infrastructure