about

predicting performances

through CAE advanced

simultations

predicting performances

through CAE advanced

simulations

Advanced CAE Analysis and Calculation Solutions – FEM and CFD Simulations

Analysis & Calculation CAE

Great expertise for innovative solutions

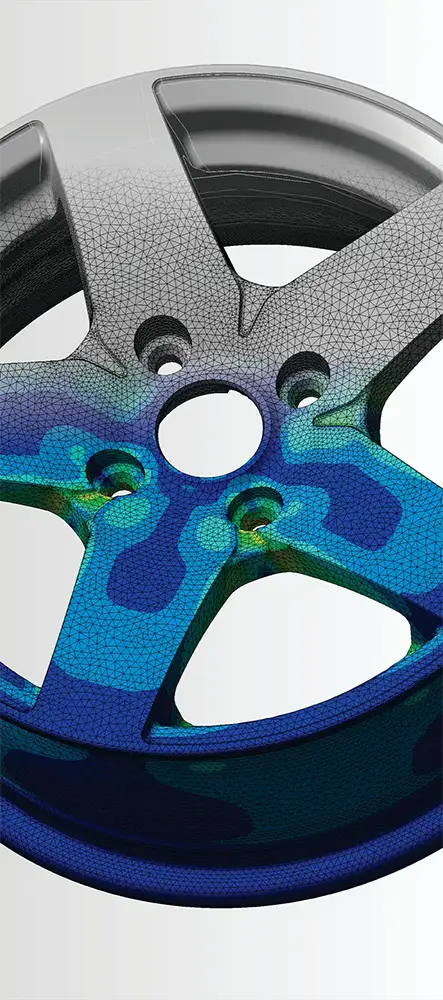

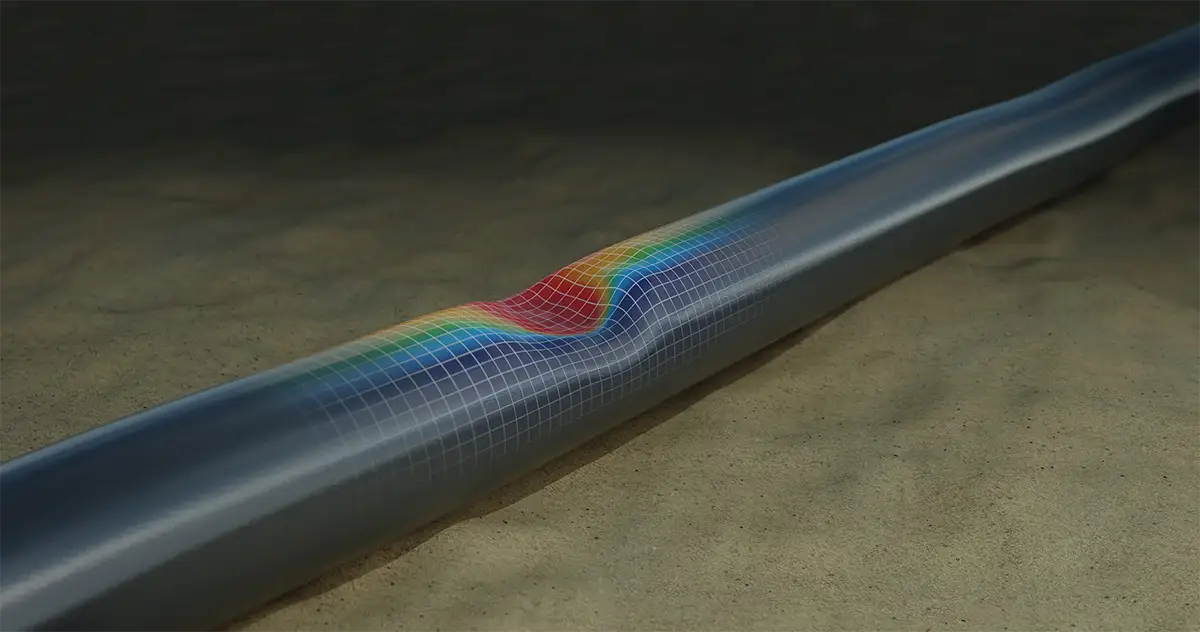

The increasing complexity of products and machinery requires predictive CAE analyses to understand behavior, improve durability, optimize performance, and reduce production costs. Our expertise in CAE analysis and calculation allows us to evaluate the technical and economic benefits of projects, lower costs, shorten time-to-market, and drive innovation. Our FEM (Finite Element Method) calculations predict structural performance, durability, and dynamic response of structures. CFD (Computational Fluid Dynamics) analyses study the aerodynamics and fluid dynamics of complex structures, identifying temperatures, flows, and pressures. Multibody analysis simulates the kinematics and dynamics of complex mechanisms, while DEM (Discrete Element Method) particle analysis and electromagnetic analyses assess the durability and performance of electric motors, PCB boards, and electronic systems.

What We Do

Advanced CAE Analysis Simulations

What We Do

- Integrated analysis with design

- Component optimization to enhance product performance

- Access to high computational power

- A skilled and flexible team of specialized CAE analysts

- Certified programs like Ansys and Altair, ensuring continuous development

- Qualified professionals presenting at seminars, university lectures, and scientific publications

- Training programs

- CAE and testing integration

FEM, CFD and Other Technical Simulations

Our technicians skills.

- FEM Analysis (Finite Element Method): Expertise in performing complex structural analyses to assess material strength and deformation.

- CFD Simulation (Computational Fluid Dynamics): Skills in modeling and simulating fluid flows to optimize aerodynamic and thermal design.

- Multibody Analysis: Experience in dynamic simulation of complex mechanical systems to study the interaction of multiple components.

- Electromagnetic Analysis: Ability to run simulations to evaluate the electromagnetic performance of devices and systems.

- DEM (Discrete Element Method) Analysis: Expertise in simulating granular and particulate materials to predict complex system behavior.

- Numerical Model Development: Ability to create and optimize numerical models to solve specific engineering problems.

- Optimization and Validation: Experience in project optimization and validation of simulation results with experimental data.

- Use of Advanced Software: Expertise in specialized software such as ANSYS, Abaqus, Fluent, COMSOL, and other simulation tools for advanced engineering analysis.

- Problem-Solving: Capability to identify and resolve complex issues through detailed analysis and innovative approaches.

- Collaboration and Communication: Ability to work in multidisciplinary teams and effectively communicate technical results and recommendations.

- Continuous Learning: Commitment to staying updated with the latest innovations and technologies in computer-aided engineering.

Our partners

- Ansys

- TecEurolab

Our team

Meet our people:

The project team

We analyze, explore, and share knowledge to enhance the efficiency and effectiveness of products and processes.

Our primary goal—improving economic competitiveness—is addressed while integrating environmental and social sustainability to ensure maximum added value.

Our primary goal—improving economic competitiveness—is addressed while integrating environmental and social sustainability to ensure maximum added value.

CAE Analysis & Calculation industries

- Amusement rides

- Equipment

- Automotive & agricolture