about

adding value

to empower your products.

adding value

to empower

your products Discover more

about

engineering precision

into every design.

engineering precision

into every design Discover more

about

integrating technology

for automated excellence.

integrating

technology

for automated

excellence

about

predicting performance through

CAE Advanced Simulations.

predicting

performance

through CAE

Advanced

Simulations

about

making complexity clear

through precise documentation.

making complexity

clear through

precise

documentation

Discover more

about

transforming ideas into

Engaging Digital Experiences

transforming ideas

into Engaging

Digital Experiences

Discover more

about

turning complexity

into clear technical

animations

turning complexity

into clear

technical animations

Discover more

It's about engineering

to innovate. Together.

Since 1996.

Innovation and Engineering since 1996

Tailored Technology Solutions with Asotech

We are Asotech, and our heart beats for engineering innovation. Every day, we are dedicated to technological advancement to offer advanced engineering solutions. Our passion for new challenges and sharing our know-how with companies allows us to create innovative solutions that improve products and optimize processes, making businesses more competitive. With our expertise, we enhance your business through cutting-edge mechanical design and integrated technologies.

Case studies

OUR OFFERING

It's

about a

total service

for complete and

integral solutions

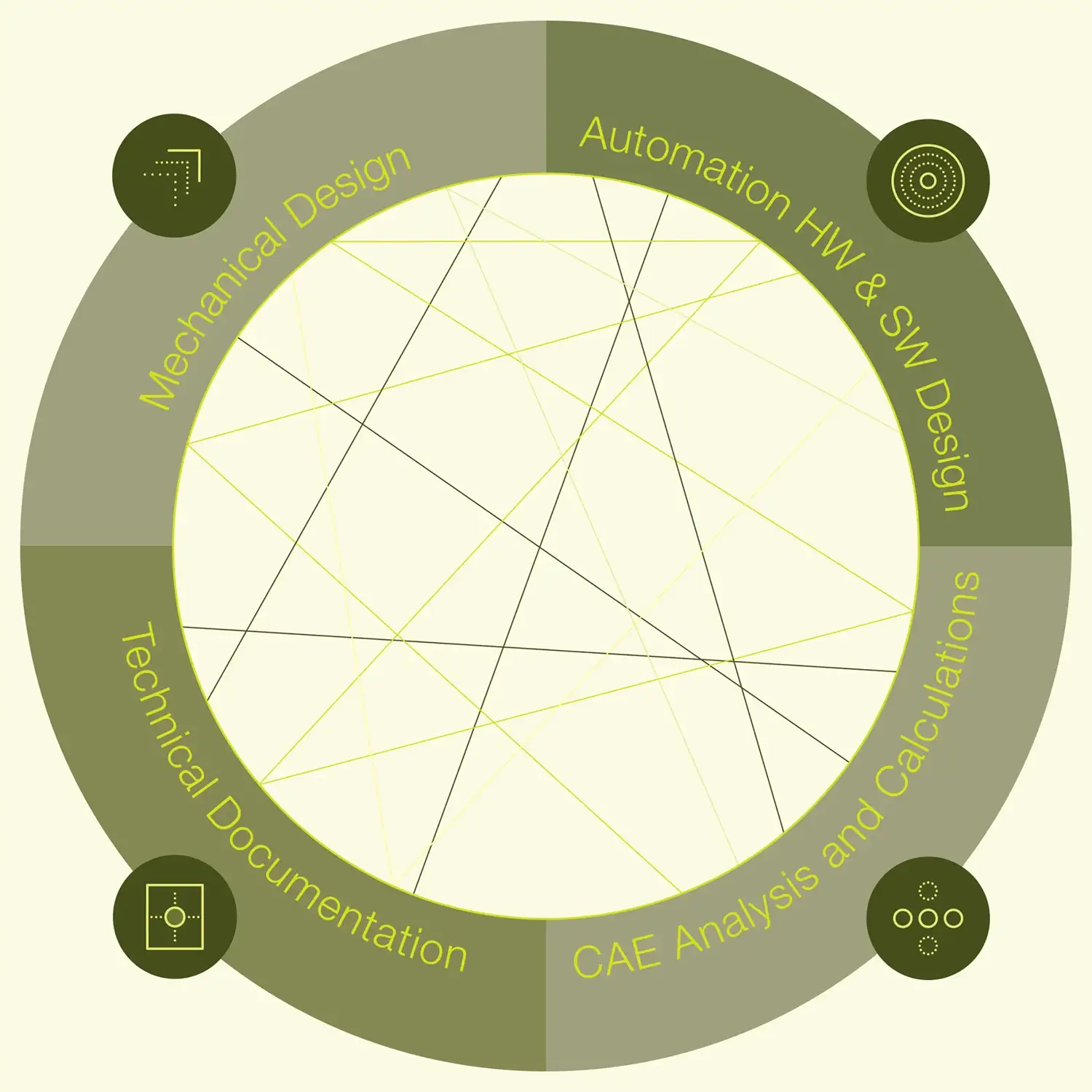

Our multidisciplinary and transversal nature is among the capabilities that set us apart. Thanks to these, we are able to work effectively in various industrial sectors, offering a service of vertical specialization. The versatility of our staff and the variety of their skills allow us to provide integrated technological solutions, adapting to the specific needs of each project.

Explore our mechanical design services, advanced CAE analysis and technical documentation to find out how we can improve the performance of your products. We also leverage the automation hardware and software to optimize production processes and ensure operational excellence. Discover our successful projects and how we can support your business.

Our team

No posts were found for provided query parameters.